Name: Steel wire rope for conveyor belt

Purpose: Suitable for steel wire rope core rubber conveyor belt skeleton reinforcement material

Features: 1. High adhesion 2. High strength 3. Excellent performance after aging

Material: 1. Carbon galvanized 2. Carbon plated copper

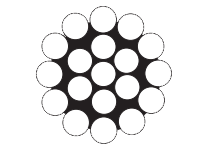

6×7-WSC | ||||||

Diameter | Toleranceon Dia | Minimum Breaking Load (KN) | Approx Weight | |||

I | Ⅱ | Ⅲ | Ⅳ | |||

mm | %D | Kg/100m | ||||

2.50 | +5-2 | 5.9 | 6.1 | 6.4 | 6.6 | 2.5 |

2.60 | 6.3 | 6.6 | 6.9 | 7.2 | 2.7 | |

2.70 | 6.8 | 7.1 | 7.4 | 7.7 | 2.9 | |

2.80 | 7.4 | 7.7 | 8.0 | 8.3 | 3.1 | |

2.90 | 7.9 | 8.2 | 8.6 | 8.9 | 3.4 | |

3.00 | 8.4 | 8.8 | 9.2 | 9.6 | 3.6 | |

3.10 | 9.0 | 9.4 | 9.8 | 10.2 | 3.8 | |

3.20 | 9.6 | 10.0 | 10.5 | 10.9 | 4.1 | |

3.30 | 10.2 | 10.7 | 11.1 | 11.6 | 4.4 | |

3.40 | 10.8 | 11.3 | 11.8 | 12.3 | 4.6 | |

3.50 | 11.5 | 12.0 | 12.5 | 13.0 | 4.9 | |

3.60 | 12.2 | 12.7 | 13.2 | 13.8 | 5.2 | |

3.70 | 12.8 | 13.4 | 14.0 | 14.5 | 5.5 | |

3.80 | 13.5 | 14.1 | 14.7 | 15.3 | 5.8 | |

3.90 | 14.3 | 14.9 | 15.5 | 16.2 | 6.1 | |

4.00 | 15.0 | 15.7 | 16.3 | 17.0 | 6.4 | |

4.10 | 15.8 | 16.5 | 17.2 | 17.9 | 6.7 | |

4.20 | 16.5 | 17.3 | 18.0 | 18.7 | 7.1 | |

4.30 | 17.3 | 18.1 | 18.9 | 19.6 | 7.4 | |

4.40 | 18.2 | 19.0 | 19.8 | 20.6 | 7.7 | |

4.50 | 19.0 | 19.8 | 20.7 | 21.5 | 8.1 | |

4.60 | 19.8 | 20.7 | 21.6 | 22.5 | 8.5 | |

4.70 | 20.7 | 21.6 | 22.6 | 23.5 | 8.8 | |

4.80 | 21.6 | 22.6 | 23.5 | 24.5 | 9.2 | |

4.90 | 22.5 | 23.5 | 24.5 | 25.5 | 9.6 | |

5.00 | 23.4 | 24.5 | 25.5 | 26.6 | 10.0 | |

5.10 | 24.4 | 25.5 | 26.6 | 27.6 | 10.4 | |

5.20 | 25.4 | 26.5 | 27.6 | 28.7 | 10.8 | |

5.30 | 26.3 | 27.5 | 28.7 | 29.8 | 11.2 | |

5.40 | 27.3 | 28.6 | 29.8 | 31.0 | 11.7 | |

5.50 | 28.4 | 29.6 | 30.9 | 32.1 | 12.1 | |

5.60 | 29.4 | 30.7 | 32.0 | 33.3 | 12.5 | |

5.70 | 30.5 | 31.8 | 33.2 | 34.5 | 13.0 | |

5.80 | 31.6 | 32.9 | 34.3 | 35.7 | 13.5 | |

5.90 | 32.6 | 34.1 | 35.5 | 37.0 | 13.9 | |

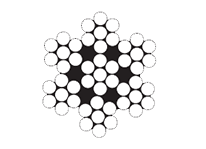

6*19-WSC | ||||||

Diameter | Toleranceon Dia | Minimum Breaking Load (KN) | Approx Weight | |||

I | Ⅱ | Ⅲ | Ⅳ | |||

mm | %D | Kg/100m | ||||

6.0 | +5-2 | 30.0 | 31.4 | 32.7 | 34.0 | 13.3 |

6.2 | 32.1 | 33.5 | 34.9 | 36.3 | 14.2 | |

6.4 | 34.2 | 35.7 | 37.2 | 38.7 | 15.1 | |

6.6 | 36.3 | 37.9 | 39.5 | 41.1 | 16.1 | |

6.8 | 38.6 | 40.3 | 42.0 | 43.7 | 17.1 | |

7.0 | 40.9 | 42.7 | 44.5 | 46.3 | 18.1 | |

7.2 | 43.2 | 45.1 | 47.1 | 49.0 | 19.1 | |

7.4 | 45.7 | 47.7 | 49.7 | 51.7 | 20.2 | |

7.6 | 48.2 | 50.3 | 52.4 | 54.6 | 21.3 | |

7.8 | 50.7 | 53.0 | 55.2 | 57.5 | 22.4 | |

8.0 | 53.4 | 55.7 | 58.1 | 60.5 | 23.6 | |

8.2 | 56.1 | 58.6 | 61.0 | 63.5 | 24.8 | |

8.4 | 58.8 | 61.4 | 64.1 | 66.7 | 26.0 | |

8.6 | 61.7 | 64.4 | 67.1 | 69.9 | 27.3 | |

8.8 | 64.6 | 67.4 | 70.3 | 73.2 | 28.6 | |

9.0 | 67.5 | 70.5 | 73.5 | 76.5 | 29.9 | |

9.2 | 70.6 | 73.7 | 76.8 | 80.0 | 31.2 | |

9.4 | 73.7 | 76.9 | 80.2 | 83.5 | 32.6 | |

9.6 | 76.9 | 80.3 | 83.7 | 87.1 | 34.0 | |

9.8 | 80.1 | 83.6 | 87.2 | 90.7 | 35.4 | |

10.0 | +4-2 | 83.4 | 87.1 | 90.8 | 94.5 | 36.9 |

10.2 | 86.8 | 90.6 | 94.4 | 98.3 | 38.4 | |

10.4 | 90.2 | 94.2 | 98.2 | 102 | 39.9 | |

10.6 | 93.7 | 97.8 | 102 | 106 | 41.5 | |

10.8 | 97.3 | 102 | 106 | 110 | 43.0 | |

11.0 | 101 | 105 | 110 | 114 | 44.6 | |

11.2 | 105 | 109 | 114 | 119 | 46.3 | |

11.4 | 108 | 113 | 118 | 123 | 48.0 | |

11.6 | 112 | 117 | 122 | 127 | 49.7 | |

11.8 | 116 | 121 | 126 | 132 | 51.4 | |

12.0 | 120 | 125 | 131 | 136 | 53.1 | |

12.2 | 124 | 130 | 135 | 141 | 54.9 | |

12.4 | 128 | 134 | 140 | 145 | 56.7 | |

12.6 | 132 | 138 | 144 | 150 | 58.6 | |

12.8 | 137 | 143 | 149 | 155 | 60.5 | |

13.0 | 141 | 147 | 153 | 159 | 62.4 | |

13.2 | 145 | 152 | 158 | 164 | 64.3 | |

13.4 | 150 | 156 | 163 | 169 | 66.3 | |

13.6 | 154 | 161 | 167 | 174 | 68.3 | |

13.8 | 159 | 166 | 173 | 180 | 70.3 | |

14.0 | 164 | 171 | 178 | 185 | 72.3 | |

14.5 | 175 | 183 | 191 | 198 | 77.6 | |

15.0 | 188 | 196 | 204 | 212 | 83.0 | |

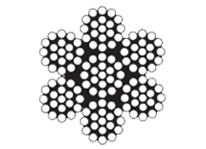

6*19W-WSC | ||||||

Diameter | Toleranceon Dia | Minimum Breaking Load (KN) | Approx Weight | |||

I | Ⅱ | Ⅲ | Ⅳ | |||

mm | %D | Kg/100m | ||||

6.0 | +5-2 | 31.4 | 32.8 | 34.2 | 35.6 | 14.7 |

6.2 | 33.5 | 35.0 | 36.5 | 38.0 | 15.7 | |

6.4 | 35.7 | 37.3 | 38.9 | 40.5 | 16.7 | |

6.6 | 38.0 | 39.7 | 41.4 | 43.0 | 17.8 | |

6.8 | 40.3 | 42.1 | 43.9 | 45.7 | 18.9 | |

7.0 | 42.7 | 44.6 | 46.5 | 48.4 | 20.0 | |

7.2 | 45.2 | 47.2 | 49.2 | 51.2 | 21.2 | |

7.4 | 47.8 | 49.9 | 52.0 | 54.1 | 22.3 | |

7.6 | 50.4 | 52.6 | 54.8 | 57.1 | 23.6 | |

7.8 | 53.1 | 55.4 | 57.8 | 60.1 | 24.8 | |

8.0 | 55.8 | 58.3 | 60.8 | 63.2 | 26.1 | |

8.2 | 58.7 | 61.3 | 63.8 | 66.4 | 27.4 | |

8.4 | 61.6 | 64.3 | 67.0 | 69.7 | 28.8 | |

8.6 | 64.5 | 67.4 | 70.2 | 73.1 | 30.2 | |

8.8 | 67.6 | 70.5 | 73.5 | 76.5 | 31.6 | |

9.0 | 70.7 | 73.8 | 76.9 | 80.0 | 33.0 | |

9.2 | 73.8 | 77.1 | 80.4 | 83.6 | 34.5 | |

9.4 | 77.1 | 80.5 | 83.9 | 87.3 | 36.1 | |

9.6 | 80.4 | 84.0 | 87.5 | 91.1 | 37.6 | |

9.8 | 83.8 | 87.5 | 91.2 | 94.9 | 39.2 | |

10.0 | +4-2 | 87.2 | 91.1 | 95.0 | 98.8 | 40.8 |

10.2 | 90.8 | 94.8 | 98.8 | 103 | 42.4 | |

10.4 | 94.4 | 98.5 | 103 | 107 | 44.1 | |

10.6 | 98.0 | 102 | 107 | 111 | 45.8 | |

10.8 | 102 | 106 | 111 | 115 | 47.6 | |

11.0 | 106 | 110 | 115 | 120 | 49.4 | |

11.2 | 109 | 114 | 119 | 124 | 51.2 | |

11.4 | 113 | 118 | 123 | 128 | 53.0 | |

11.6 | 117 | 123 | 128 | 133 | 54.9 | |

11.8 | 121 | 127 | 132 | 138 | 56.8 | |

12.0 | 126 | 131 | 137 | 142 | 58.8 | |

12.2 | 130 | 136 | 141 | 147 | 60.7 | |

12.4 | 134 | 140 | 146 | 152 | 62.7 | |

12.6 | 138 | 145 | 151 | 157 | 64.8 | |

12.8 | 143 | 149 | 156 | 162 | 66.8 | |

13.0 | 147 | 154 | 160 | 167 | 69.0 | |

13.2 | 152 | 159 | 165 | 172 | 71.1 | |

13.4 | 157 | 164 | 171 | 177 | 73.3 | |

13.6 | 161 | 168 | 176 | 183 | 75.5 | |

13.8 | 166 | 173 | 181 | 188 | 77.7 | |

14.0 | 171 | 179 | 186 | 194 | 80.0 | |

14.5 | 183 | 192 | 200 | 208 | 85.8 | |

15.0 | 196 | 205 | 214 | 222 | 91.8 | |